Quality assurance process followed by TS16949 procedure

1) First Article Stage:

l Develop initial inspection plan and quality criteria.

l Material chemical element Inspection and record

l Full dimension measurement and record

l Form/fit/function inspection and record

l Cosmetic Inspection and record

2) Pre Production Stage:

l Develop updated inspection plan and quality criteria

l Create process flow diagram and control plan

l Whole process from material and final product audit and record

l Key process and product data collection to evaluate the process capability

l Sampling inspection of semi and final production and keep record

l Target sample, max pass sample signed and recorded

3) Production Stage

l Sampling AQL inspection of both semi product and final product

l Routine audit of whole process

l Continue improvement though every corrective actions plan

l Weekly quality meeting including process and product quality

Our Test, Inspection and Measurement Capability

l Material tested by spectrometer

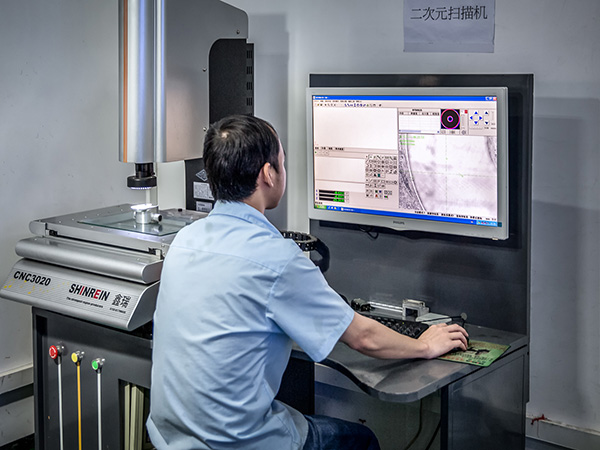

l Dimensions measured by reasonable measurement tools at different stage, caliper, micrometer, 2D projector and CMM.

l Physical property test including tensile strength test, metallographic analysis equipment, X-ray inspection machine, hardness tester……