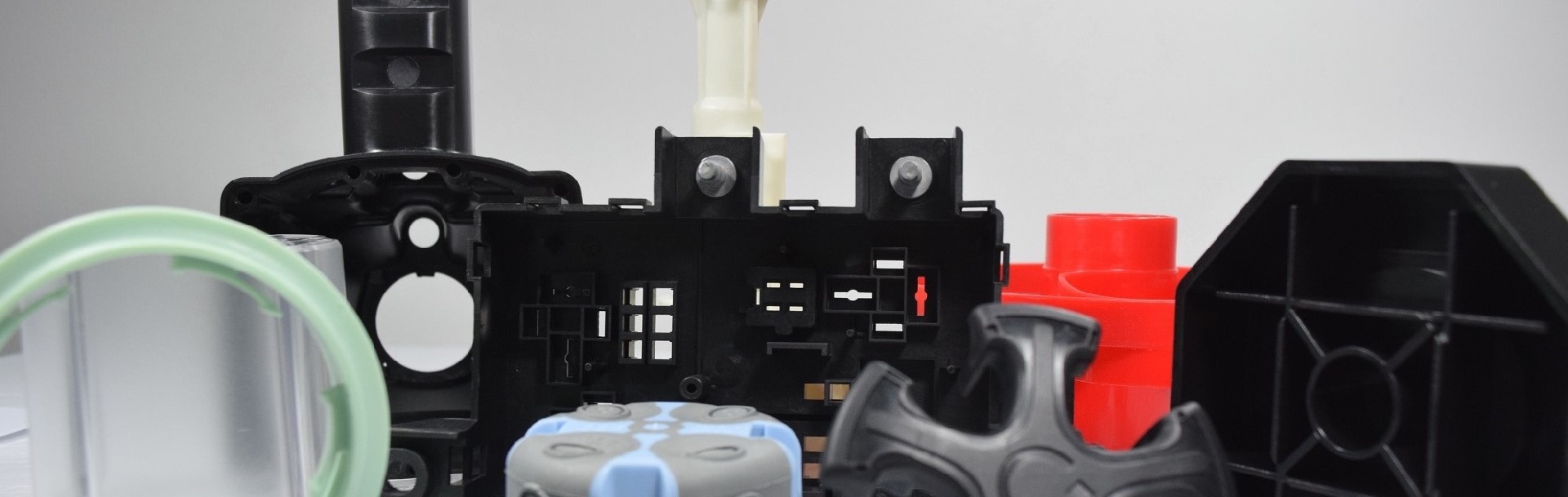

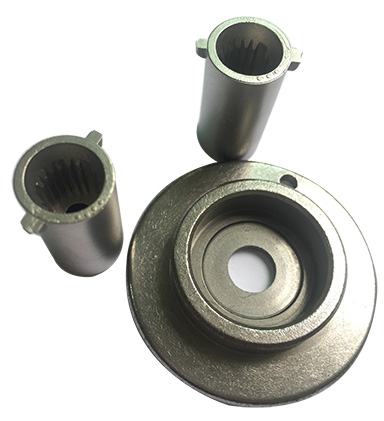

Rapid Injection mould and moulding part defines the mold focus on the low volume plastic parts production, this is one of the most cost effective solution for the low volume customized plastic part and also used to fill the gap between plastic prototyping and mass production.

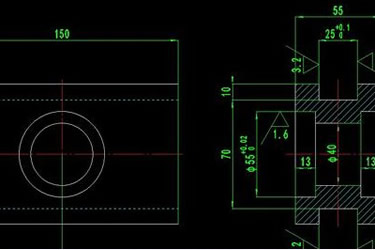

Normally, the life cycle of the rapid tooling is between 5000 to 50000 shots. To achieve this small goal, the “rapid mold” often designed as 2 plate mold, direct injection gate, a shared mold base, manual slider and less expensive mold core/cavity material. The only purpose to design the rapid mold is to shorten the lead time and save cost. Max prototype have the proved capability to complete a mold as fast as 7 days and as cheap as 2000 USD.

Max prototype is a professional rapid injection mold manufacturer and provide rapid tooling only, not production mould. We have provided about 80 rapid injection mold project in 2016, we always focus on continue improvement to optimize the mold design, mold assembly, molding trial and production process.