1 Raw Material: Every type of incoming metal material will be tested by spectrometer and resuls also be recorded.

2 First Article: Full dimension inspection on 100% part including dimension, assembly, cosmetic. Any defects will report to customer to make sure Max prototype clearly understand customer quality requirement. All inspection followed by documented specific product inspection plan and inspection results will be recored on internal product inspection template.

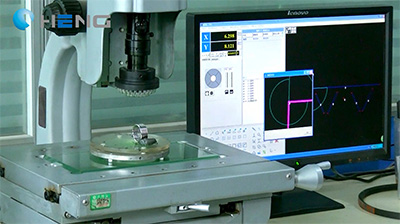

3 Process Control: All parts with low volume to high volume order will do first piece inspection, in process routine inspection and final AQL sampling inspection. For higher volume order, we will follow the PPAP procedure to manage both manufacturing process and final product quality.

4 QA Inspection: Open box to do sampling inspection followed by product critical dimension, function and features. All inspection followed by updated specific inspection plan and inspection results will be recorded on internal inspection template.