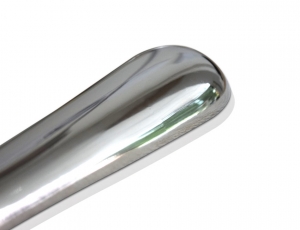

1 All necessary inspection tools and test equipment are in place based on internal quality control procedure or follow customer requirement (CMM inspection machine, chemical composition test Equipment, metal graphic test machine , X-ray test machine, slurry related test tool kits, Tensile strength test machine, salt spray test machine and others)

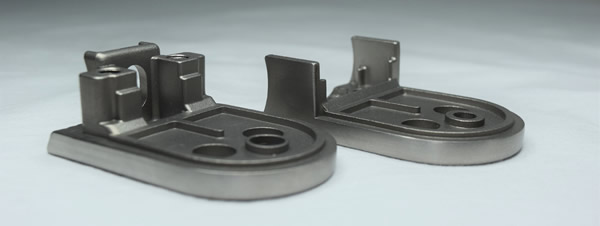

2 Mold design and manufacture in house and documented mold design and mold inspection report

3 First article inspection and record (dimension, physical property and cosmetic), Inspection is based on investment casting inspection plan and casting parts linear tolerance guideline.

4 Production trial (PPAP procedure introduced, working instruction of each process and Investment Casting Process Control Plan of whole production process in place, Target sample and specific product quality criteria in place).Please take a look at one example of the whole information about the stainless steel product invesment casting process control plan.

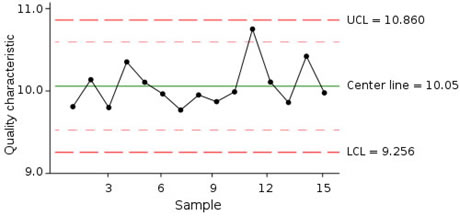

5 Evaluation of Production trial (Process audited report, data collected from key process, process capability study, quality criteria revised)

6 Mass production (Routing process audit, sampling inspection for semi-part and final part). Inspection is also based on updated investment casting inspection plan and casting parts linear tolerance guideline.

7 Continue improvement procedure (corrective action plan) applied in any small specific quality issue and common quality issues in whole manufacturing process. The effectiveness of all corrective actions will be routine evaluated for further improvement, this procedure will repeat agin and agin untill specific issues resolved and passed the audit.

8 All above quality management tools, procedures and quality inspection results is always documented by QA team, which allow us to have the capability to trace back in details and much easiler to find out the root cause in case of quality rejects was addressed.