Project Description:

Project Name: Ball Valve (Medium Pressure).

Industry Applied: Petroleum chemical industry.

Customer: From USA.

Order Volume: 4500 sets per year.

Toyota production system applied in production, TS 19649 procedure applied in quality assurance, PPAP procedure applied in trial run audit and approval.

1) Product information:

5 inches Valve

Overall dimensions: 306 x 250 x 218mm (h)

Weight: 17.95Kg

Material: Stainless Steel 304

Thickness: 12.0mm to 18.0mm

2.5 inches Valve

overall dimensions: 188 x 185 x 146mm (h)

Weight: 6.95Kg

Material: Stainless Steel 304

Thickness: 8.0mm to 12.0mm

0.5 inches Valve

Overall dimensions: 88 x 112 x 56mm (h)

Weight: 0.910 Kg

Material: Stainless Steel 304

Thickness: 5.0mm to 7.0mm

2) The whole casting process:

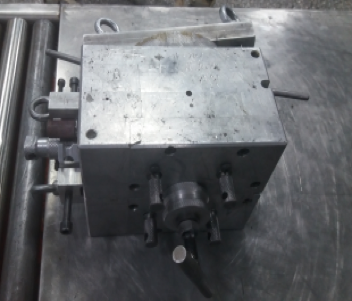

a) Wax injection mold, machined by DMG 5 axis CNC machine

b) Wax Part: material type is K114 from Japan with melt point at 77 Celsius. Shrink rate 1.1%. This type of wax applied to all casting project made by our company.

c) Max injection weight of the injection machine: 3.0 Kg

d) Shell mold: normally apply 5 to 6 layer of slurry plus 5 to 6 layer of sand to build the strength of the shell. First layer play a big role of final casting parts quality

First layer of slurry: silica sol + zirconium oxide powder, applied to all casting parts

First layer of sand: Zirconium oxide, applied to all casting parts

e) De-waxing process, all wax to be removed by below machine, hot moisture at high temperature to guarantee 100% wax to be removed before casting.

f) Heat up the shell, melt the metal. Medium frequency electromagnetic induction furnace. Maximum casting weight per month: 300 tons per month.

g) Chemical composition test by spectrometer analyzer. Applied to every furnace, every production line and every day.

h) Remove the shell by bead blasting and sand blasting process

i) Cut the pouring gate.

j) Heat treatment based on product requirement

k) Further Surface treatment based on product requirement

Rest process did not show up here, our company has strong capability do post CNC machining, grinding, polishing, sandblasting, painting and PVD in house.